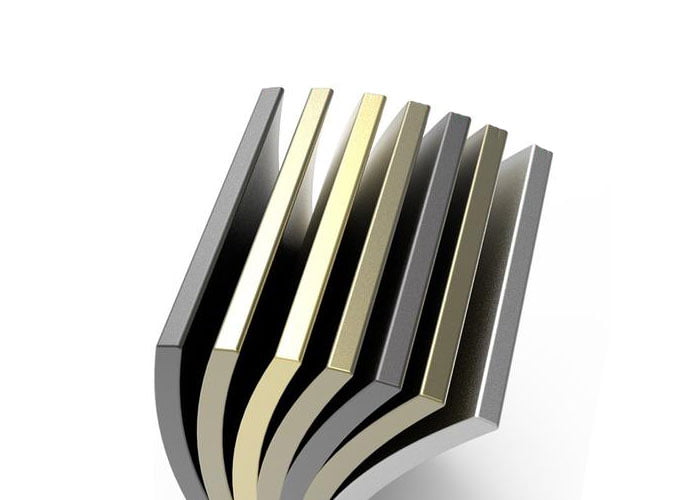

Take a look at the production process of triple-layered steel cookware

Three-layer steel pot production process is an important process, steel quality, production technology, process, is the key to manufacturing high-quality, high-efficiency three-layer steel pot. The following will introduce the three-layer steel pot production process

Raw material preparation

In one case, the bottom layer of the three-layer steel pot to choose a thick production of two-layer steel pot is the key to selecting the right raw materials, good raw materials is also an important factor to protect the quality of the three-layer steel pot.

Degree of 3 to 5 mm stainless steel plate or copper plate; the middle layer of aluminium, copper or metal alloys; the surface layer of good gold materials.

Plate processing

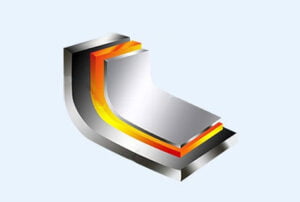

Sheet processing is mainly the raw material processing, will be moulded into three layers of steel pot bottom, wall, cover. Bottom processing:First cut the stainless steel plate into the right size, and then grind it to achieve the requirements of no burr and no depression. Wall and cover treatment:Turn, bend and weld the plates on the machine to become wall and cover. High-temperature protective gas is selected for welding to prevent the metal from oxidation, corrosion and other damages. Three-layer structure assembly

The bottom, wall and cover are completely fixed together by welding to become a strong whole. When welding, the temperature, time and welding quality should be strictly controlled to ensure that the welds are tight and undamaged.

sandblasting

After the welding is completed, it is necessary to go through the sandblasting process to remove the surface grit and polish the surface more smoothly, and when grinding, it is necessary to choose the appropriate technology and equipment according to different metal materials.

Surface treatment

The surface treatment of three-layer steel pot is divided into two kinds: mechanical polishing and chemical polishing. Mechanical polishing requires the use of appropriate grinding tools and abrasives, fine grinding of the surface. Chemical polishing is the use of special chemicals, chemical reactions on the surface, so as to achieve the removal of stains, smoother effect.

Cleaning and drying

After the completion of production needs to be cleaned and dried to ensure that the product meets the health standards, cleaning, you need to choose a special cleaning agent, in accordance with a certain proportion of cleaning, and the use of high-temperature drying procedures to make it completely dry.